Read Mold Siliocn Rubber :

Creating molds for silicone molding typically involves a few key steps:

Model Preparation: Begin with a model or prototype of the object you want to replicate. This can be made from various materials such as clay, wood, plastic, or even a 3D-printed object.

Mold Box Construction: Build a mold box around the model to contain the silicone rubber. This can be made from materials like wood, plastic, or foam board. Ensure that the mold box is sturdy and can be easily disassembled after the mold is made.

Model Sealing: Seal the model to prevent the silicone rubber from leaking out during the molding process. This can be done using various sealants or mold release agents depending on the material of the model.

Mold Material Selection: Choose a suitable material for making the mold. Silicone rubber is commonly used for this purpose due to its flexibility, durability, and ease of use. Other options include polyurethane rubber or latex rubber, depending on the specific requirements of the project.

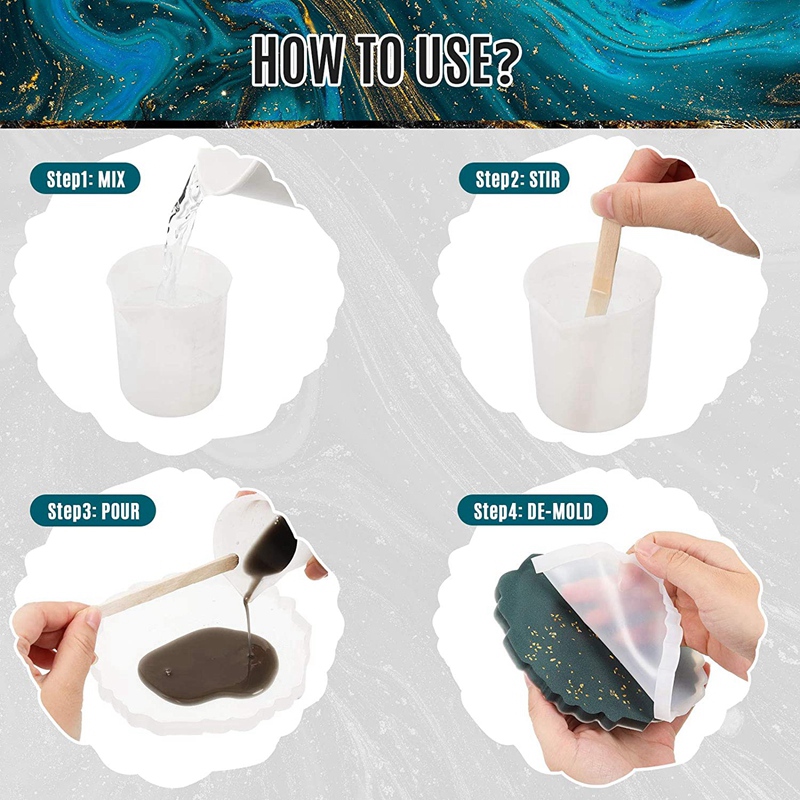

Mixing and Pouring: Mix the silicone rubber according to the manufacturer's instructions. Ensure thorough mixing to avoid any uncured spots in the mold. Pour the mixed silicone rubber into the mold box, covering the model completely.

Curing: Allow the silicone rubber to cure or set according to the manufacturer's recommendations. This typically involves waiting for a specified amount of time for the silicone to fully cure and harden.

Demolding: Once the silicone mold has cured, carefully remove the mold box and separate the mold from the model. Depending on the mold design, you may need to cut or split the mold to facilitate easy removal.

Cleanup and Finishing: Trim any excess silicone rubber and clean up the mold as needed. You can also make additional modifications or refinements to the mold surface if necessary.

Mold Maintenance: Properly store the silicone mold when not in use to prevent damage or deformation. Regularly inspect the mold for any signs of wear or damage, and make repairs or replacements as needed.

By following these steps, you can create high-quality silicone molds for use in various molding applications, including casting resin, plaster, wax, and other materials.

For More Info

Conatct : Jay Enterprises Bangalore

Ph : 8050657801 / 8884343524